For some, solar power is about clean electricity, while others find the financial aspects of it most compelling. Still others, a very important batch of people, want the independence that distributed electricity generation offers.

With independence comes responsibility though, and one responsibility is that your solar system needs to be able to handle the rough and tumble that reality often gives us. The US Federal Emergency Management Agency has put out guidelines to help small scale solar owners survive a hurricane.

On that note, the U.S. Department of Energy’s National Renewable Energy Laboratory has released Solar Photovoltaics in Severe Weather: Cost Considerations for Storm Hardening PV Systems for Resilience. The document reviews thirteen techniques for hardening a solar power system and gives the costs of these upgrades. There are also multiple degrees of system upgrade that the report offers, to allow you to fine tune your system design based on local and financial conditions, as well as levels of risk aversion.

First is the list of thirteen solar power hardening tips and their cost premiums. The report analyzed upgrade costs for a 1 MW solar ground mount with a fixed tilt racking system, and a 100 kW rooftop solar installation. This list was based upon prior research, including this 2018 document released by the Department of Energy, and this Rocky Mountain Institute report (both of which CommercialSolarGuy recommends you review).

The first thing the document suggests is properly tightening – or more technically said torquing – your bolts. The document suggests that a post installation audit will give you a decent feeling on the quality of your torquing and whether you need to torque every connection. Do note that if the same team that installed also torque audits, this resilience work may be subject to the same mistakes or price pressures as the initial work.

When choosing locking hardware, avoid split washers, nylon nuts, serrated flanged nuts, and double nutting, as these technologies are proven ineffective under Junker testing—the industry standard vibration test. Wedge-lock washers are one example of a highly effective, economical class of locking hardware.

The next suggestion considers that your torquing on day one might have been spot on, but that over time, and especially under times of heavy vibrations, these connections may loosen. A collection of fasteners are recommended, starting with wedge-lock washers and finishing with thread lock that will help to lock in hardware.

A hard reality that will hit many is seen in the image to the left, a CommercialSolarGuy installation. Note the piece of hardware holding the solar panel in place – this is a type of clamp. It holds down the module using fraction. Research strongly suggests that in hurricane prone regions, this technique simply isn’t viable.

Researchers say that through bolting, which connects solar modules directly to solar racking with a bolt, give the structural strength needed to survive severe weather events. Surprisingly, for ground mount installation, the cost of the technique is quite low – 0.2 to 0.5¢/W, with the majority of the cost being in the labor. This same technique on rooftops is a bit more challenging and labor intensive as there’s no easy under the system access like a ground mount.

Suggestion #4 is using Marine Grade (salt/corrosion resistant) steel products, which the researchers found is already a common practice in markets that necessitate its use. Another local market choice is picking out solar panels that have thicker frames, or additional frame bars to increase their strength.

Another technique to increase the strength of systems is to increase the number of connections between the solar module and the attachment location – roof or ground. Highlighted in the document is a CommercialSolarGuy installation in Miami-Dade, Florida in which we had to meet local wind code requirements of 175 mph+. The local authority having jurisdiction requested we install a third rail – as can be seen in the above image.

This added the cost of the additional rail, flashing units to connect the system to the structure, and the labor to make 50% more attachments. The researchers suggested this added 5.7¢/Wdc for a rooftop solar installation. For ground mount installations, heavier rail and slightly refined ground connection techniques also offered stronger – but expensive – upgrades.

The most expensive component suggested was a wind calming fence.

For a 1 MW project, the fence costs 14¢/Wdc on top of the standard costs that are required for most projects (estimated at 5.9¢/Wdc). The estimated adder costs are $100 to $150/foot of fencing. As projects scale, this number falls quickly.

Perimeter rows of solar modules are generally under the most forces during wind events, absorbing and breaking up the energy before inner rows are affected. The fence does work at breaking up the wind as well.

It was here that the researchers did state that a fence would work in conjunction with other strengthening techniques, and it was up to your engineers to make judgment calls on the combination of techniques to spend the time and money on. The paper noted, “There is no one-system-fits all solution and it is crucial for system engineers to design to the site conditions, project constraints, and the developer’s acceptable level of risk.”

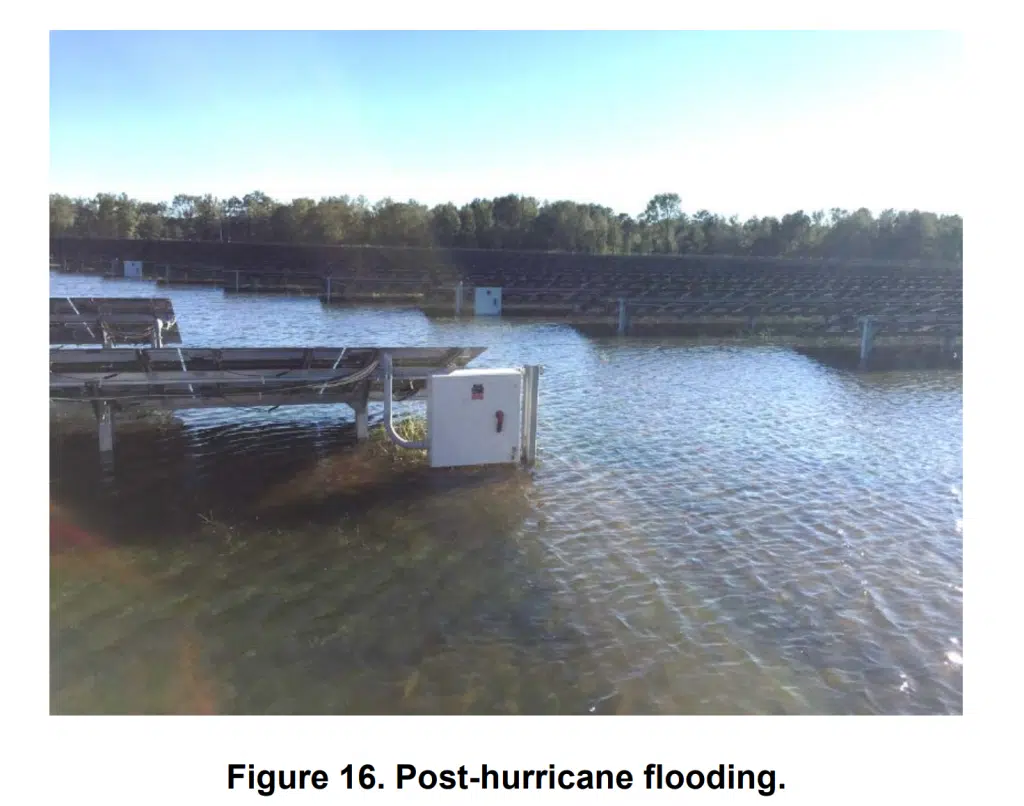

Flooding events got attention in three ways – first by choosing and engineering smart sites, second by mounting gear on pads, and last by installing and maintaining the drainage systems.

In general, the core of the system measures appear to be less expensive than outside of system measures. Performing system audits and focusing on appropriate fasteners are the least expensive of the storm hardening measures we analyzed. In regions with a high likelihood of severe weather, however, additional measures, such as a three-rail system or two-pier mounting, may be necessary to protect a PV array.

And in case you’ve already installed your system, and didn’t have a chance to do it already, field research has suggested that a post installation inspection might find issues, with a non-trivial percentage being critical. The inspections done in this document can be done by a homeowner on their own system.