Standard thickness for solar cells is generally 100-150 μm. So 57 μm is half to almost a third. Since the cost of polysilicon is the greatest cost in a solar panel – dropping the total volume of poly is significant.

LONGi heterojunction solar cell achieved a certified power conversion efficiency of 26.06% with a thickness of 57 μm

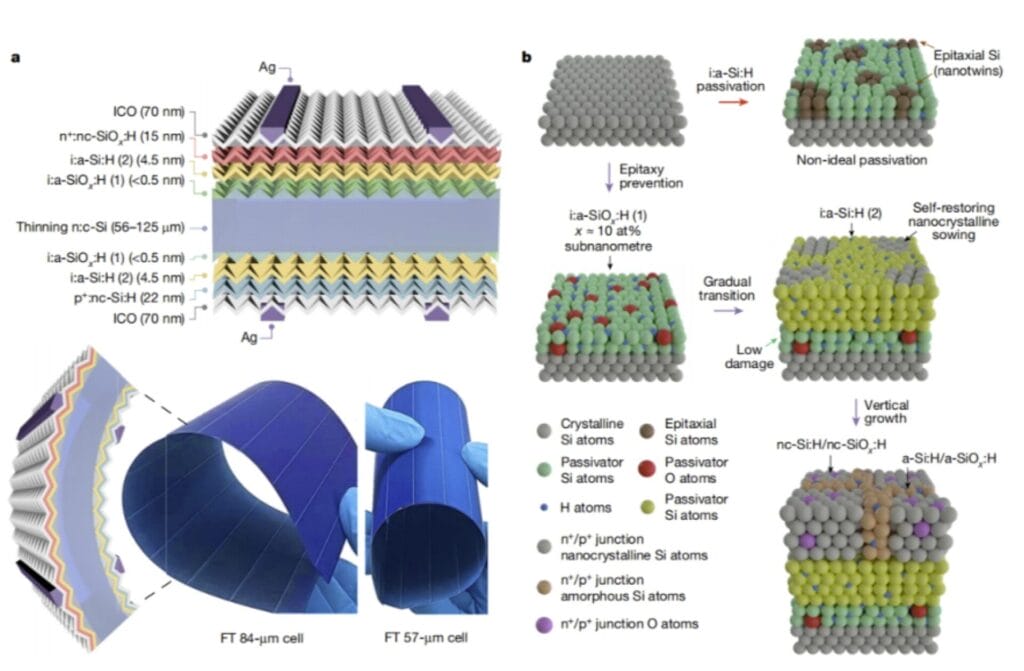

cell achieved a certified power conversion efficiency of 26.06% with a thickness of 57 μm, a value of 26.56% with a thickness of 106 μm, and a maximum efficiency of 26.81% with a thickness of 125 μm. The 57 μm solar cell had also the highest power-to-weight ratio (1.9 W g−1) and open-circuit voltage (761 mV).

able to reduce optical loss by optimizing the configuration of grid lines using “industry-compatible contact-free” laser transfer printing technology. “The finger width could be reduced from 40 μm (typical screen printing) to 18 μm, with the shading area controlled to less than 2%,” they noted.

Link and a second, more technical, source