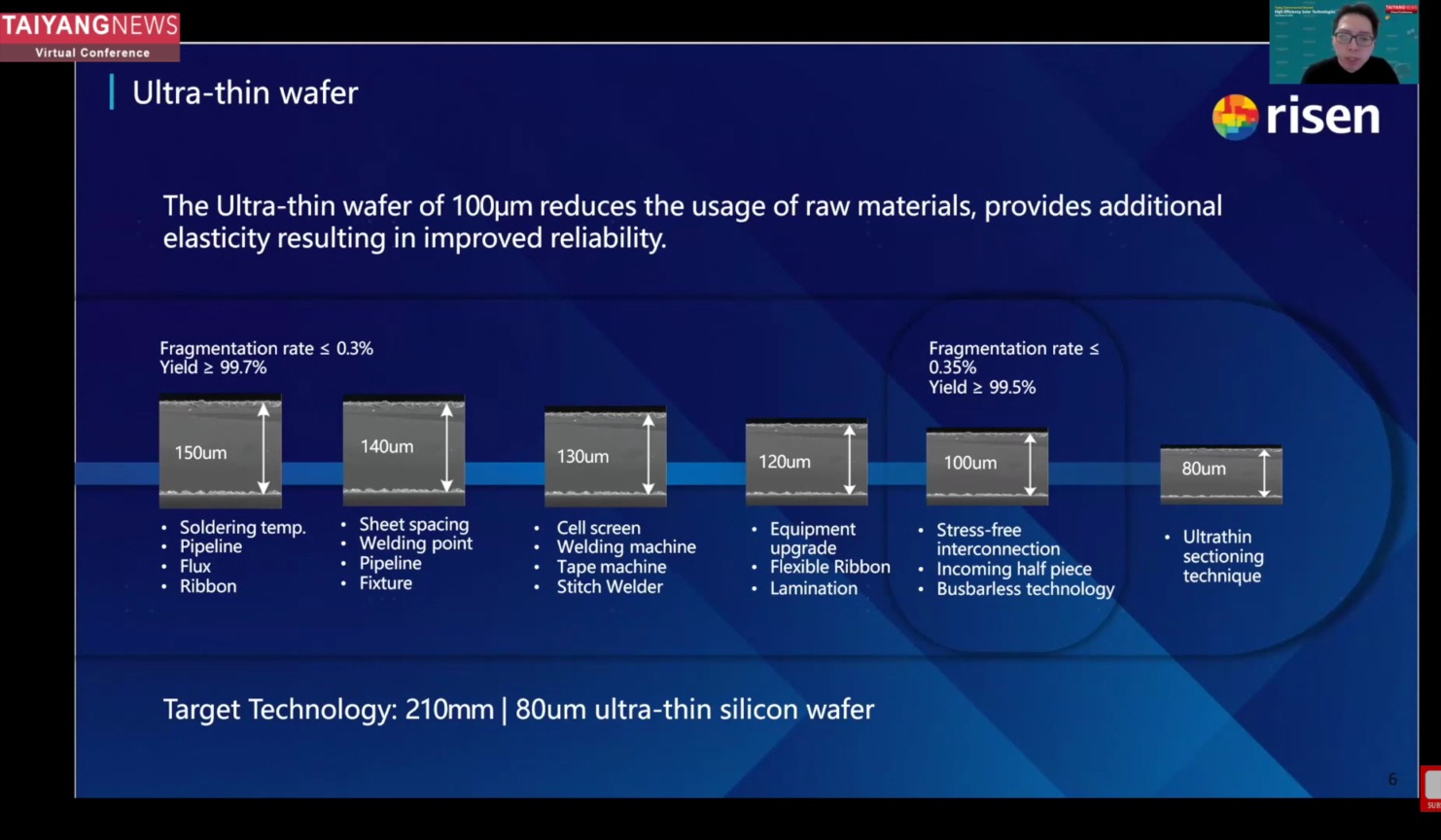

Risen replaced its 150 µm wafer with a much thinner and flexible 100 µm wafer for its Hyper-ion HJT cell

By October 2023, its busbarless 100 µm Hyper-ion HJT Cell realized a 25.8% average production efficiency

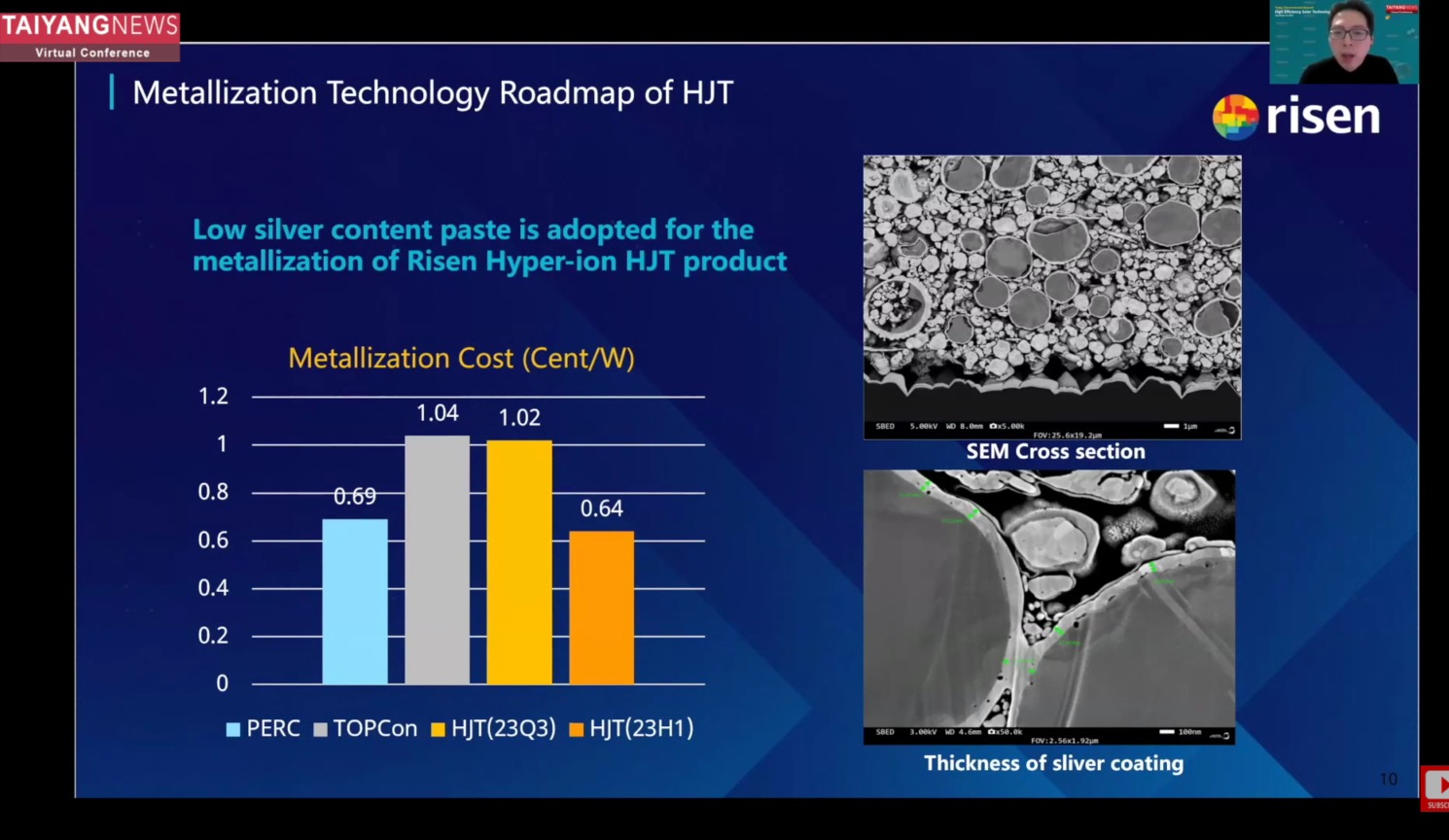

Adoption of 50% low silver content metallization paste reduces metallization cost to 1.02 c/W

JT, the 2 key factors for Risen to invest in HJT are low LCOE and low carbon footprint

processing costs for HJT are a real concern as the technology requires a higher amount of silver paste, while TCO is a completely new material compared to PERC and TOPCon

after reducing wafer thickness from 150 µm to 100 µm, the same optical absorbance level was observed up to 700 nm light wavelength

negative impact of wafer thinning to 100 µm or even slightly lower is negligible.

during the test, the 150 µm PERC cell started to crack when deformation reached 46.74 mm, followed by the 130 µm TOPCon cell at 53.68 mm deformation

the HJT cell with thickness did not crack at the maximum point of load test at deformation, ensuring mechanical stability

production data showing the yield with ultra-thin wafers reached 99.2% and the breakage rate reduced to 0.2%

silver-coated copper paste with 50% silver content to reduce silver consumption

reduced metallization costs to 1.02 c/W

expecting to reach 0.64 c/W this year

plans to cut the silver content further to close to 40% this year to reduce the usage of silver from 10 mg/W to 7 mg/W, corresponding to 50% and 40% silver content, respectively