Energy storage safety is not a game:

UL has released its report on the energy storage fire at the McMicken Energy Storage facility located in utility Arizona Public Service territory just outside of Phoenix. Julian Spector, whose been reporting on this event from early on, covered the report from the utility’s perspective (which includes a great technical document by DNV GL & APS).

The system was installed by Fluence Energy, and built of LG Chem Li-ion battery cells and modules.

This article will mostly focus on the UL document, which was compiled by the UL Firefighter Safety Research Institute. And whose purpose is to offer recommendations on how to improve codes, standards, and emergency response training to better protect first responders, maintenance personnel, and nearby communities.

At 4:54:30 PM, on April 19, 2019, remote monitoring systems received notifications of an anomaly at a lithium ion battery facility in Surprise, Arizona.

Module 2 of Rack 15, in a 2 MW/2.16 MWh energy storage plant, saw its battery cell voltage quickly decrease. Fourteen seconds later the air temperature at the top of Rack 15 began to rapidly increase from 104°F to a peak of 121.6°F.

Thirty seconds later smoke alarms were set off, throwing all DC circuit breakers, AC inverter contractors, and the main AC breaker. Thirty seconds after that, suppression systems built into the 50 foot long shipping container shaped system were discharged.

Just short of an hour later, firefighters in Phoenix got a call of smoke and an acrid smell coming from a local electrical substation. Three minutes later, the power company’s remote monitoring system received its last notification from the battery plant.

Firefighters from the Surprise Fire-Medical Department responded to the incident within eight minutes. The Surprise team elevated the call to the Peoria Fire-Medical Department Hazardous Materials team, who arrived thirty minutes later.

After arrival and over the course of an hour, the hazmat team made three entries into the fenced in area, and specifically a “hot zone” area surrounding the battery. They measured HCN and CO concentrations, as well temperatures 360 degrees around the site. The data collected noted a temperature decrease and that the hot spot grew geometrically smaller.

The teams officially communicated that the site was trending toward safer, and began to formulate a plan of entry into the structure to determine internal conditions – specifically if there was an active fire. Upon opening the door of the facility, dense gases and vapors were observed flowing out.

Captured in the frames above is the hazmat team opening the container door, and beginning measurement of internal conditions – temperature, chemical concentrations, visual inspection, etc.

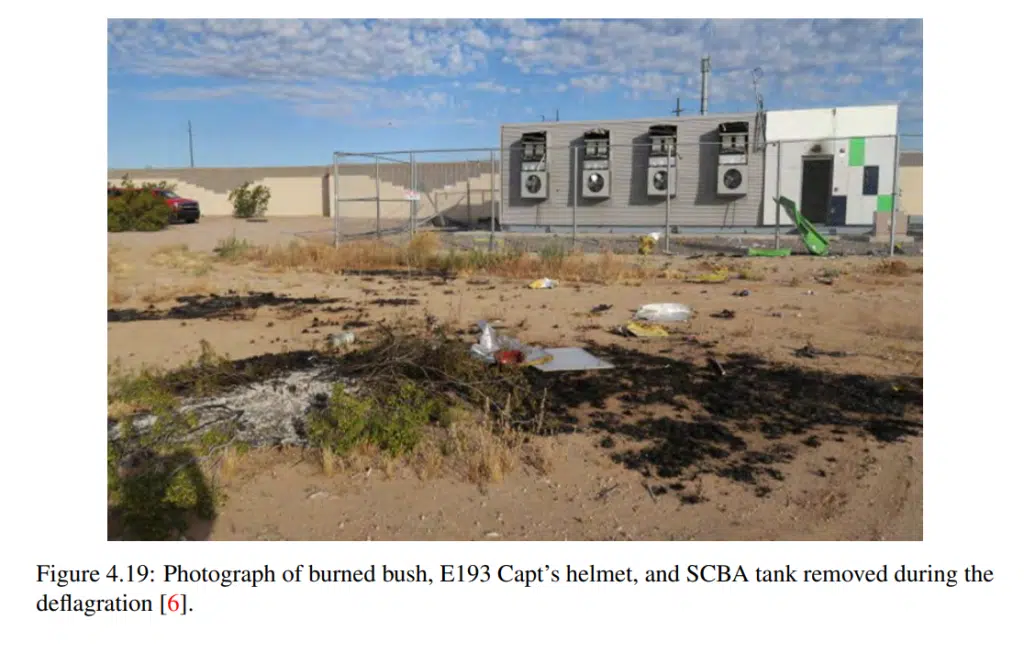

At the moment of the deflagration event, the firefighters outside the hot zone described hearing a loud noise and seeing a jet of flame that extended at least 75 ft outward and an estimated 20 ft vertically from the southeast-facing door. In the event, E193 Capt and E193 FE were ballistically propelled against and under the chain-link fence that surrounded the ESS. E193 Capt came to rest approximately 73 ft from the opened door beneath a bush that had ignited in the event. E193 FE came to rest approximately 30 ft from the opened door. HM193 FF1 was projected toward the transformer and distribution box to the east of the ESS and remained within the fenced area. The entire HAZMAT team lost consciousness in the deflagration event. The event also dislodged or removed the SCBA face pieces and helmets from all of the HAZMAT team members.

Extensive injuries occurred. All members survived.

The UL report’s recommendations were half toward learning new techniques to manage energy storage, and the other half in training response professionals. The report offered six technical recommendations to lithium-ion battery and energy storage facility manufacturers/managers:

- Lithium-ion battery ESSs should incorporate gas monitoring that can be accessed remotely.

- Research that includes multi-scale testing should to be conducted to evaluate the effectiveness and limitations of stationary gas monitoring systems for lithium-ion battery ESSs.

- Lithium-ion battery ESSs should incorporate robust communications systems to ensure remote access to data from the BMS, sensors throughout the ESS, and that the fire alarm control panel remains uninterrupted.

- Lithium-ion battery ESSs should incorporate adequate explosion prevention protection as required in NFPA 855 or International Fire Code Chapter 12, where applicable, in coordination with the emergency operations plan.

As noted in Specter’s article, APS shut down its other battery facilities from facility owner Fluence — one at Festival Ranch, which is a twin of the McMicken system, and a larger one at the desert community of Punkin Center. Before those reopen, they will need to be retrofitted with ventilation systems.