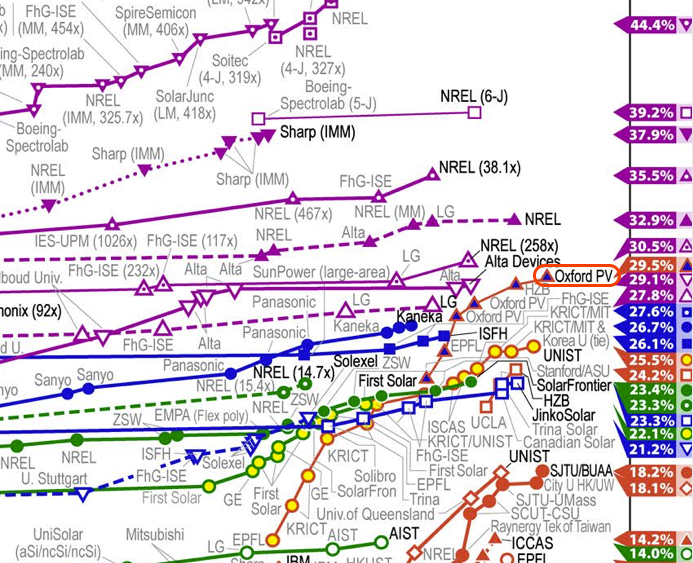

On December 21, 2020 OxFord PV announced that they set a new record for a perovskite-silicon tandem research solar cell at 29.52%. The perovskite cell was placed atop a monoPERC NType silicon solar cell. This efficiency percentage broke the very recently set record of 29.15% by Helmholtz-Zentrum Berlin, who had just announced their solar cell on December 11, 2020.

This record matters because we see silicon single layer solar cells topping out in the 26-27% range, and because 35 kg of perovskite might be able to generate the same amount of electricity as seven tons of silicon (½ of 1%).

OxfordPV CTO Dr Chris Case estimates that moving their record efficiency lab solar cell (29.52%) to the manufacturing floor will be a three year development process. Case says the company expects product efficiency to increase by ~1% per year. So far they have exceeded their target with increases of 1.3% per year.

The company announced a record solar cell efficiency of 27.3% in the summer of 2018. The goal is to roll a product roughly meeting these targets using their 125 MW/year manufacturing line at a rate of one 7 watt solar cell every two seconds.

Thus, the 29.5% solar cell might be available for purchase sometime in 2025. A solar panel’s efficiency will be ~2% lower than the solar cell itself. See for example the recent 24.9% Jinko record efficiency silicon solar cell and the subsequent 23.01% solar panel record. This implies that perovskite-silicon solar panels may arrive with 27.5% real world efficiency by mid-decade.

Case sees the residential road map going all the way to a 33% efficient solar cell with the current technology series, and minimal technology changes.

“Beyond 33%, an advanced version of what we do, we might see two perovskites combined with silicon – or something else – hitting 39 to 43%.”

Now, for the meat and potatoes (efficiency records are gravy in this analogy) – When, where, how much can I buy one of these panels for? The timeline has slowed since CommercialSolarGuy’s prior article projecting availability this summer. Current projections indicate availability early in 2022.

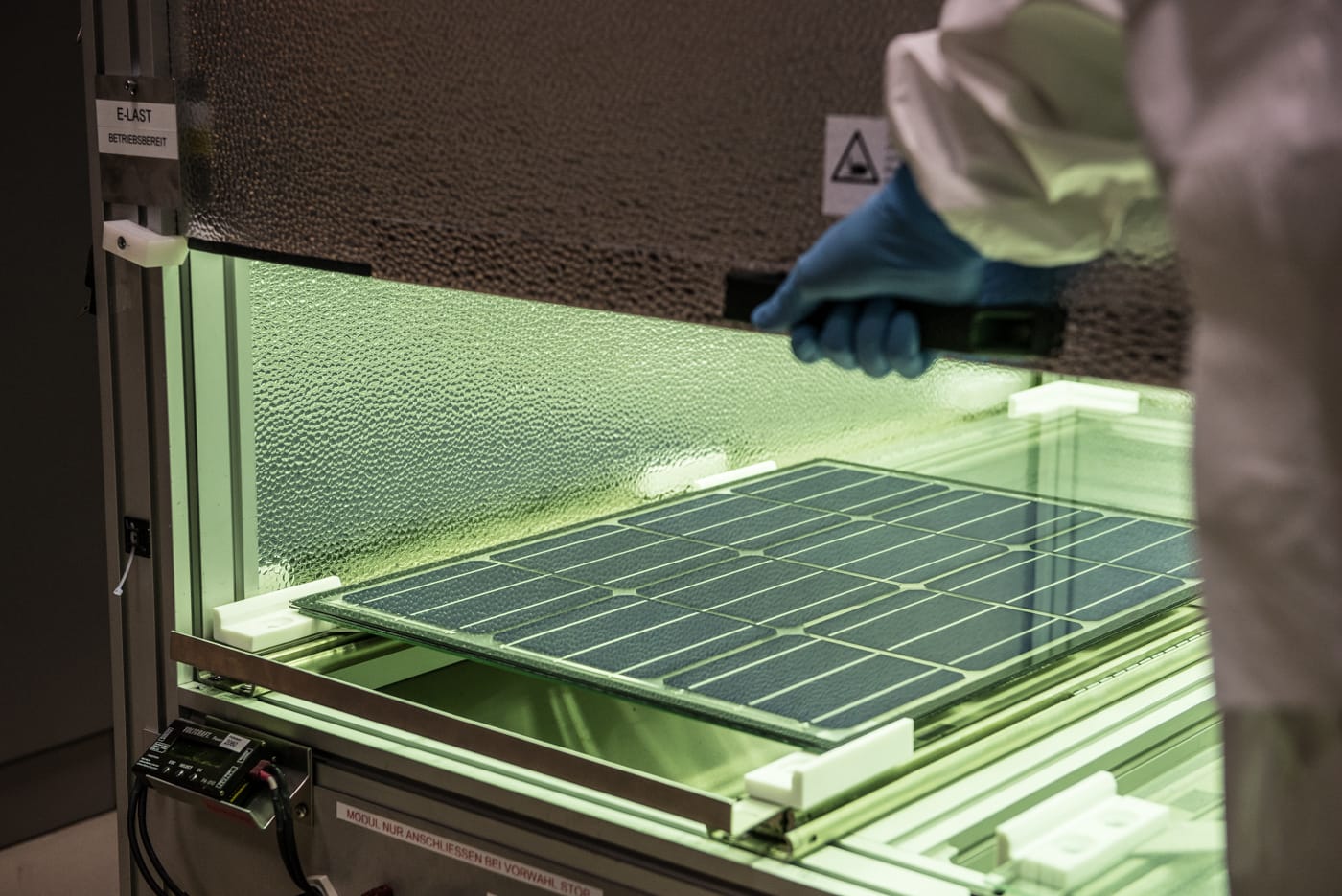

Since 2017, Oxford PV’s low volume pilot line located in Germany has been producing test solar cells. More recently, the product that has come off of this line has passed internationally recognized testing standards for product longevity. When these key documents become available, we’ll be sure to share them.

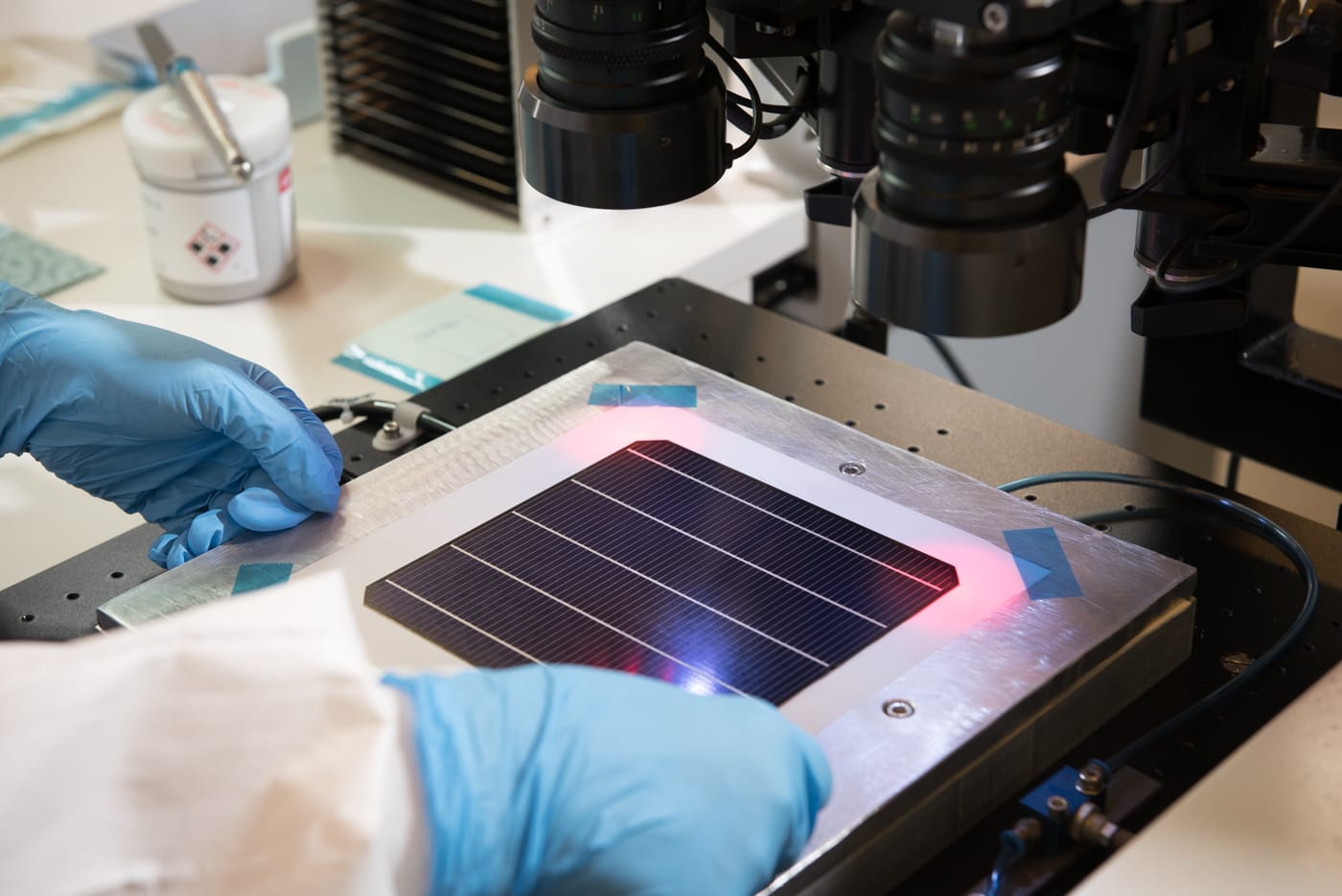

“Bottom cell is heterojunction n-type – nominal efficiency of the bare cell is 23.5% (if it were finished as a cell. Of course we don’t put on the normal front metal because we deposit the perovskite cell first) Cell size is M6” – Oxford PV

In the prior article – written in the spring of 2020 – it was noted that there was a dance going on due to covid to be able to scale up from the pilot line to the volume line.

The two shifts of engineering teams were isolated from each other, but their work was dependent upon the other group being able to complete their work. This meant that if one person got infected with covid on one team, no matter what, it affected everyone.

A ‘complex workflow’ is the way CEO Frank P. Averdung described the work to build the machines, whose own work was also quite complex. Case reminded us that the machine workflow’s goal is to deliver 7 watts every two seconds.

The German manufacturing facility – during the machine installation phase – was shut down as the first wave of covid hit. The facility reopened in the summer of 2020 – but it was shut down again, and restarted again, in the fall. With new covid variants a new reality, both the CEO and CTO worked to reign in this author’s hardware enthusiasm.

- The timeline right now looks something like this:

- Facility upgrades ready by the end of Q1’2021.

- Full system start in the beginning of Q2

- The beginning of process integration starting in Q2, and finishing in Q3

- Internal solar cell testing in Q3

- Ramping of solar cell manufacturing, and delivering to manufacturers, in Q3.

- ~Six months of manufacturer certification upon receipt

- Q1’22 for potential market availability.

This commercial line will deliver cells that should build a solar panel of 425 watts in the standard 60 cell residential format.

As we are still in the midst of a global pandemic, which is still peaking in some places of the world, so OxfordPV will need some luck to maintain their current timeline. So good luck to them, and to ourselves.